BEST INNOVATION AWARD- 2018

SAGAR TOOLS AND MACHINES

WOMAN ENTERPRISE and WINNER OF “BEST INNOVATION AWARD- 2018” at National Science Center, Pragati Maidan – NEW Delhi, by Ministry of Science and Culture, Government of India. For it’s innovative product “Cycle Atta Chakki”

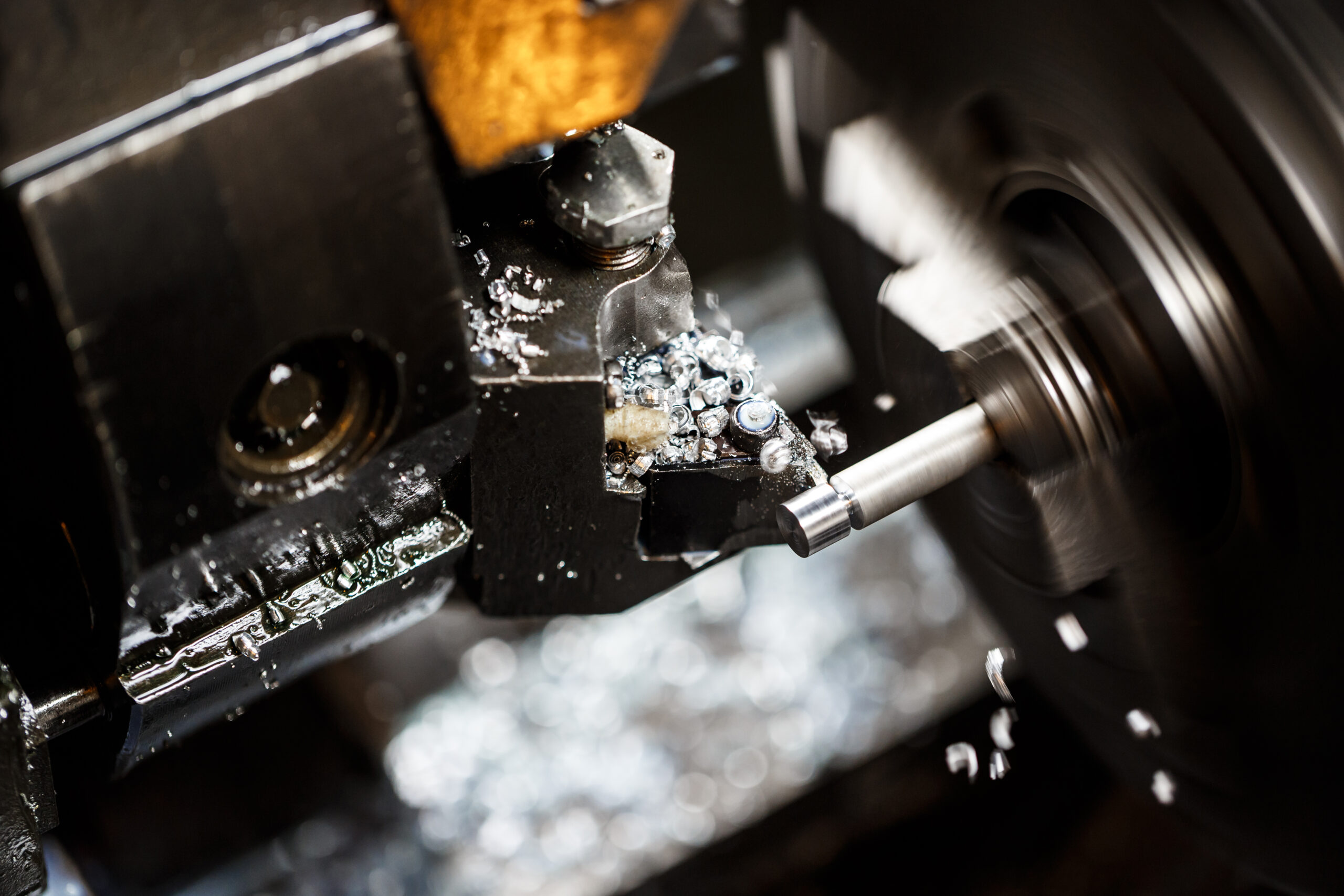

Specifics: JOB Work for CNC Milling (VMC) and CNC Wirecut.

our project

Machines & Facilities in our workshop

- CNC Wire-cut machine – 3 Machines

- VMC/CNC Milling machine (Bed size – 500x550x600, accuracy in 5 microns)

- Cylindrical Grinding machine

- Lathe machines (6 feet and 9 feet ) – TWO Machines

- Milling machines M1TR with DRO – TWO Machines

- Surface grinder, bench grinder and hand grinders with buffing facilities

- Pencil grinder

- Drill machines

- Shaper machine

- Cutting and surface finish machines

- All instruments used are Mittutoyo (made in Japan)

FOCUS: Key customers: Customers are the main focus for us, nothing is more important than satisfying our customer by serving their needs and providing them perfect solutions. To give value to our KEY customers, we make a drive to dedicate teams and SPOC (single point of contact) to our key customers. Our ultimate goal is to make “Sagar Tools & Machines” a default choice for our customers. Striving for the quality and timeliness is our guiding force.

Adding new customers: Our policy is to Serve 🡺 Assess our skills 🡺 Enhance🡺 Sustain 🡺 Expand. Adding new KEY customers with dedicated team to replicate what is being done already with our existing KEY customers. Above steps are to ensure that we don’t compromise on our services to existing customers by adding new ones.

Our Capabilities: We have a strong team with 15 skilled technical expert people, mix of technical expertise, management and councilors. 8 dedicated operators ITI, 2 BE Mechanical engineers and one dedicated resources for QUALITY control & two for customer relations. We also have a dedicated engineer for R&D and new product development. We have strong network of mechanical engineers and designers who help us as and when required.

Apart from the new product development we also develop punch, DIEs, Jigs and fixtures, plates, flenges, gauges and machine parts etc. with high precision profiles. We have developed the products in 10 micron accuracy. Commitment for quality and timeliness is key to us.